October 15, 2024 | Protocast Inc

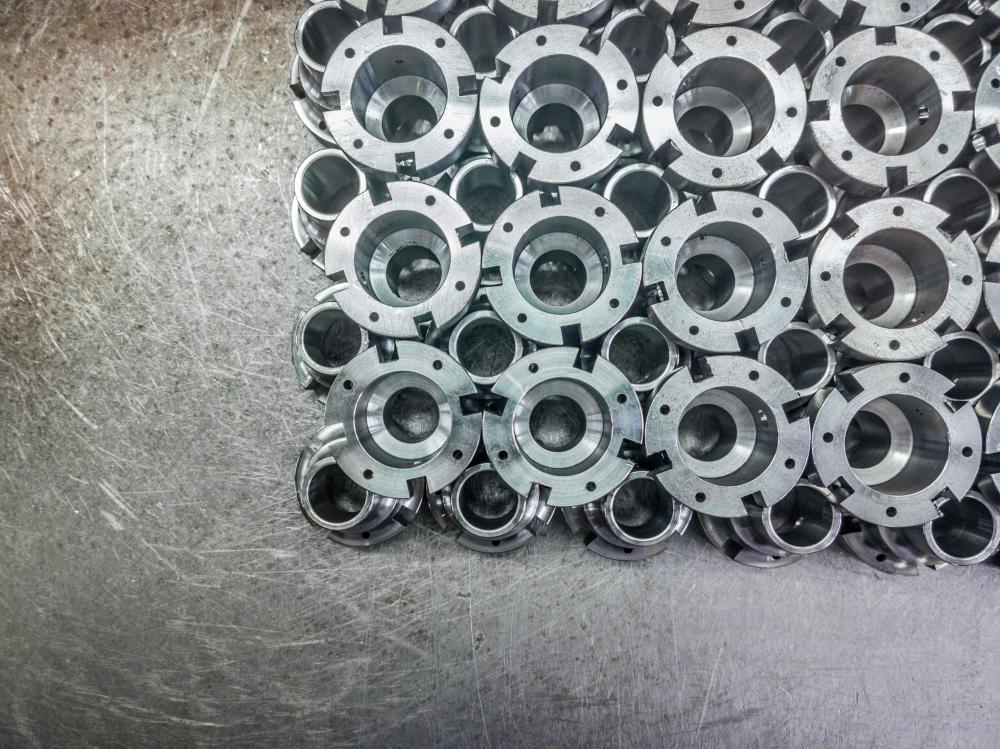

Aluminum Die Cast Ohio

The Basics of Aluminum Die Cast

At Protocast Inc., we’ve navigated the complex world of casting metals and have found a sweet spot with aluminum die cast. This process has allowed us to deliver high-quality components that meet the rigorous demands of various industries. But what makes aluminum die cast stand out? Let’s dive deep into its core.

What Makes Aluminum Ideal for Die Casting?

Aluminum’s lightweight nature combined with exceptional strength forms the backbone of its suitability for die casting. Its high thermal and electrical conductivity are cherries on top, making it a prime choice for automotive, aerospace, and electrical industries. In our journey of crafting parts, we have leveraged these inherent qualities of aluminum to push the boundaries of what can be achieved through die casting.

Advantages of Aluminum Die Cast

Choosing aluminum die cast as a manufacturing process brings forth a parade of benefits. Its capability to produce complex shapes with high dimensional stability allows us to cater to intricate design requirements. Here’s a closer look at why aluminum die cast stands out in our foundry:

- Efficiency and Rapid Production: Aluminum die casting enables us to produce large quantities of parts with meticulous precision, swiftly meeting the demands of our clients.

- Durability: Parts manufactured through this process are robust, withstand high temperatures, and have excellent corrosion resistance.

- Lightweight Products: The lightness of aluminum, paired with the strength it offers, is unbeatable for many applications, especially in the automotive and aerospace sectors.

- Recyclability: At Protocast Inc., sustainability is a priority. Aluminum’s recyclability aligns with our commitment to environmentally friendly manufacturing practices.

The Protocast Edge

Our expertise in aluminum die cast doesn’t just lie in the technicalities but also in our approach to every project. We view each client as a partner, offering personalized advice to select the most suitable casting method. It’s not just about making parts; it’s about crafting solutions that fit perfectly into the bigger picture of what our partners are trying to achieve.

Customized Solutions for Industries

Whether it’s aerospace, automotive, medical, or consumer products, our aluminum die cast services have been tailored to meet specific industry needs. This adaptability has been powered by our deep understanding of industry-specific requirements, allowing us to deliver beyond expectations.

Quality Assurance at Protocast

Quality is not just a buzzword at Protocast Inc.; it’s the foundation of everything we do. Our ISO 9001:2015 certification and Itar Registration echo our commitment to excellence. Every aluminum die cast part we produce undergoes stringent testing to ensure it meets the high-quality standards our clients expect.

Continual Improvement

Our journey in the world of aluminum die casting is marked by continual learning and improvement. We invest in cutting-edge technology and refine our processes to stay a mile above other foundries. Our dedicated team brings passion and innovation to the table, driven by the desire to solve complex challenges and deliver excellence.

Navigating Challenges in Aluminum Die Cast

In our years of experience, we’ve encountered and overcome numerous challenges in aluminum die casting. From managing the high temperatures required for casting aluminum to dealing with the intricacies of mold design, each challenge has been an opportunity to grow. Our proactive problem-solving approach ensures that we deliver robust solutions, even in the face of complex technical demands.

Case Studies of Success

Our portfolio is a testament to the wide array of challenges we’ve overcome. Each project, whether it was producing lightweight yet sturdy parts for the automotive industry or intricate components for medical devices, has added a layer of depth to our expertise.

Future Directions in Aluminum Die Casting

The future of aluminum die casting is as bright as ever. With advancements in technology and materials, we are at the cusp of a new era where the boundaries of what can be achieved are constantly expanding. At Protocast Inc., we are excited to be part of this journey, embracing innovation to meet the evolving needs of our partners.

Embracing Innovation

As we look forward, our focus remains on leveraging new techniques and materials to enhance our aluminum die cast offerings. We are committed to staying ahead of the curve, ensuring that our partners benefit from the latest advancements in the field.

Protocast Inc. prides itself on being at the forefront of the aluminum die casting industry. Our dedication to quality, efficiency, and innovation drives us to deliver outstanding results for every project we undertake. Contact us today to explore how we can bring your ideas to life with our expert casting services.

What is aluminium die cast?

Aluminium die casting is a precision casting method where molten aluminium is injected into a mold under high pressure. At Protocast Inc., we’ve perfected this process to create parts with unparalleled dimensional accuracy and intricate details. The beauty of aluminum die cast lies in its ability to produce lightweight but strong components, making it a favorite among industries ranging from aerospace to automotive. The process not only allows for the production of complex shapes but also ensures consistency across large production runs.

Is die cast aluminum cookware good?

From our expertise in aluminum die casting, we can say that die cast aluminum cookware has its advantages. It’s known for even heat distribution, which is crucial for cooking. Also, it’s lightweight, making it easier to handle. However, when choosing cookware, it’s essential to consider that the surface should be treated or coated to avoid direct food contact with aluminum, ensuring safety and durability. So, while die cast aluminum cookware can be a good choice, it’s important for consumers to select high-quality, well-coated products.

Is aluminum die cast safe to use?

Aluminum die cast parts are widely used across various industries due to their durability and strength. Concerns usually arise when it comes to food contact or consumer goods. At Protocast Inc., we ensure that our aluminum die cast products are manufactured and finished according to industry standards, making them safe for their intended uses. For applications involving direct food contact, proper coatings are applied to prevent any health risks. It’s all about how the aluminum is processed and used; with the right measures in place, aluminum die cast products are perfectly safe to use.

Can 6061 aluminum be die cast?

Technically, 6061 aluminum is challenging to die cast due to its composition, which is not ideal for the high temperatures of the die casting process. At Protocast Inc., we typically recommend other aluminum alloys that are better suited for die casting. This doesn’t mean 6061 aluminum can’t be used in manufacturing; it’s actually quite popular for its weldability and strength, but it’s more commonly processed through methods like machining or forging. For those looking to achieve the characteristics of 6061, we advise exploring alternative alloys that are more conducive to die casting while still meeting the project’s specifications.

What makes Protocast Inc.’s aluminum die cast process stand out?

Our aluminum die cast process at Protocast Inc. is refined to deliver precision, efficiency, and custom solutions. What sets us apart is not just our ability to produce high-quality parts but also our approach to problem-solving and innovation. We work closely with our partners to understand their needs, suggesting the most suitable alloys and design modifications to achieve the best outcomes. Our investment in the latest technology and a commitment to continual improvement enables us to tackle challenges head-on and push the boundaries of what aluminum die casting can achieve. This collaborative and innovative mindset has been key to our success and our partners’ satisfaction.

How does Protocast Inc. ensure quality in aluminum die casting?

Quality at Protocast Inc. goes beyond certifications and standards. It’s embedded in every step of our aluminum die casting process. From the initial design consultation to the final inspection, we apply rigorous quality control measures. Our ISO 9001:2015 certification and Itar Registration are testaments to our systematic approach to quality. We utilize advanced testing methods to evaluate the mechanical properties and integrity of our castings, ensuring they meet the precise specifications of our clients. Moreover, our dedicated team of professionals is trained to identify and address potential issues early in the process, preventing costly reworks and ensuring the delivery of superior quality parts on time.

Resources

- Aluminum Casting: Overview and Design Guidelines – Visit here

- Aluminum Die Casting: Advantages and Applications – Visit here

- Aluminum Die Casting: Process, Advantages, and Applications – Visit here

- Aluminum Die Casting: Sustainability and Recycling – Visit here