Protocast Inc. Offers Different Processes to Manufacture Your Parts

The ability to select the most appropriate process based on the design requirements of the part allows us to tailor our solutions to our customer’s needs. From Rapid Investment casting using a lost wax process, or Printed Sand Mold casting, both of which are suitable for making smaller quantities of parts to limited production. With Air Set Precision Sand casting, Permanent Mold Casting and Die Casting services for production quantities, we have a process that fits the job.

When the part is too large for our lost wax investment casting process, and the number of parts doesn’t justify hard tooling, we can offer castings using one of our core processes. We can cut soft tooling and then cast in Precision Sand. We can also utilize a printed sand mold process. Additionally, we are fully capable of machining parts from stock.

Each process we offer has advantages and limitations. Our sales staff and engineers analyze each job to ensure we’re using the appropriate process for the job based on a number of factors.

Engineering Support

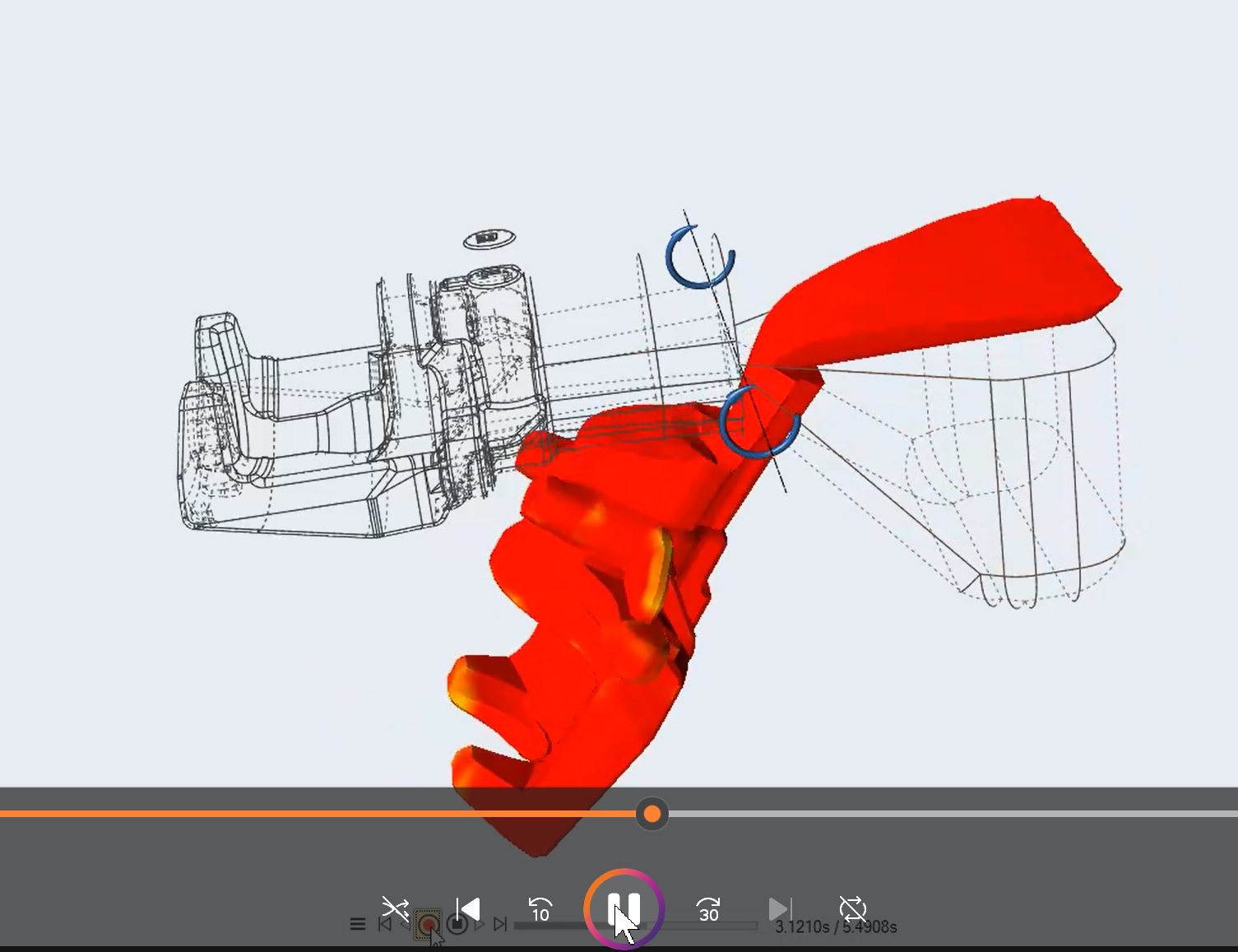

Nearly half of our employees hold engineering degrees. From basic feedback on casting and machining, to reverse engineering, 3D CAD modeling, and Computation fluid analysis, our engineering department is capable of supporting projects large and small.

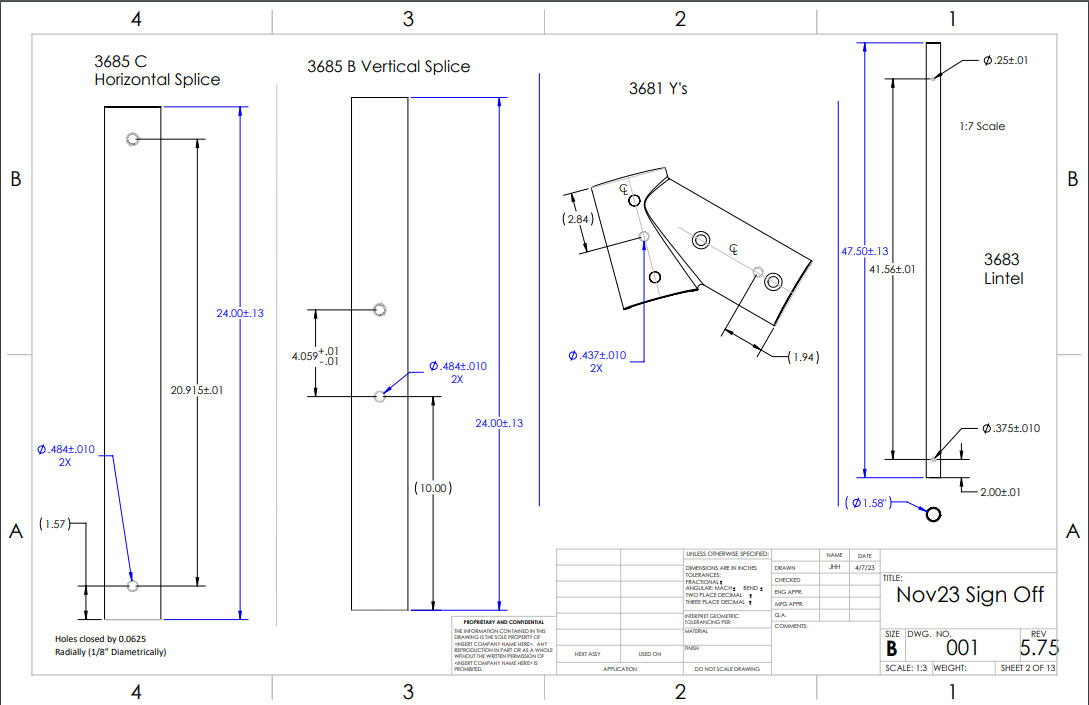

Drafting Services

Protocast offers drafting and print generation services. ***Disclaimer*** Protocast does not engineering castings or components for customers.

Toolmaking

If the foundry you typically use is experiencing longer than normal lead times, we can often engineer and cut matchplate tooling in a matter of weeks instead of months. We have 3 CNC machines dedicated to tool cutting operations.

CNC Machining

Specializing in machining of cast prototypes means our machinists and engineers are experts in the unique challenges presented by castings.

Heat-Treating

Using our in-house heat treatment system, we are able to heat treat most aluminum castings to T6 condition in 2 to 3 days from receipt of parts.

Inspection & Testing

With an in-house CMM we can perform most dimensional inspections on-site. We have experience with a variety of customer defined pressure and leak tests as well.