The Importance of Low Pressure Aluminum Casting

At Protocast Inc., we consider low pressure aluminum casting to be a cornerstone of the metal casting industry, particularly for aerospace, automotive, and consumer products. This technique not only allows for the creation of high-quality components but also offers unparalleled flexibility in design and material integrity. Through this method, molten aluminum is introduced into a mold at low pressures, enhancing the quality of the casting and allowing for the creation of complex shapes with high precision.

Why Low Pressure?

The industry preference for low pressure aluminum casting stems from its ability to produce parts with smoother surfaces and more refined details compared to other methods. The low turbulence during the metal flow minimizes porosity and enhances the mechanical properties of the final product. This process is particularly beneficial for producing parts that require high structural integrity, such as those used in critical applications in the aerospace and automotive industries.

Benefits of Low Pressure Casting

One of the primary advantages of low pressure aluminum casting is its efficiency. By allowing for the use of permanent molds, we at Protocast Inc. are able to significantly reduce both production times and costs. Furthermore, this casting process is incredibly versatile, enabling us to cater to a wide range of industry needs with precision and reliability.

Quality and Consistency

The controlled environment of low pressure aluminum casting results in parts that are consistent in quality and dimension. Our clients can expect components that meet their exact specifications, batch after batch. This consistency is crucial for industries where safety and performance are paramount.

Design Flexibility

Our team values the design flexibility that low pressure aluminum casting offers. It opens a realm of possibilities for complex geometries and intricate details that would be difficult, if not impossible, to achieve with other casting methods. This flexibility allows our clients to explore innovative designs and solutions for their products.

Applications in Industries

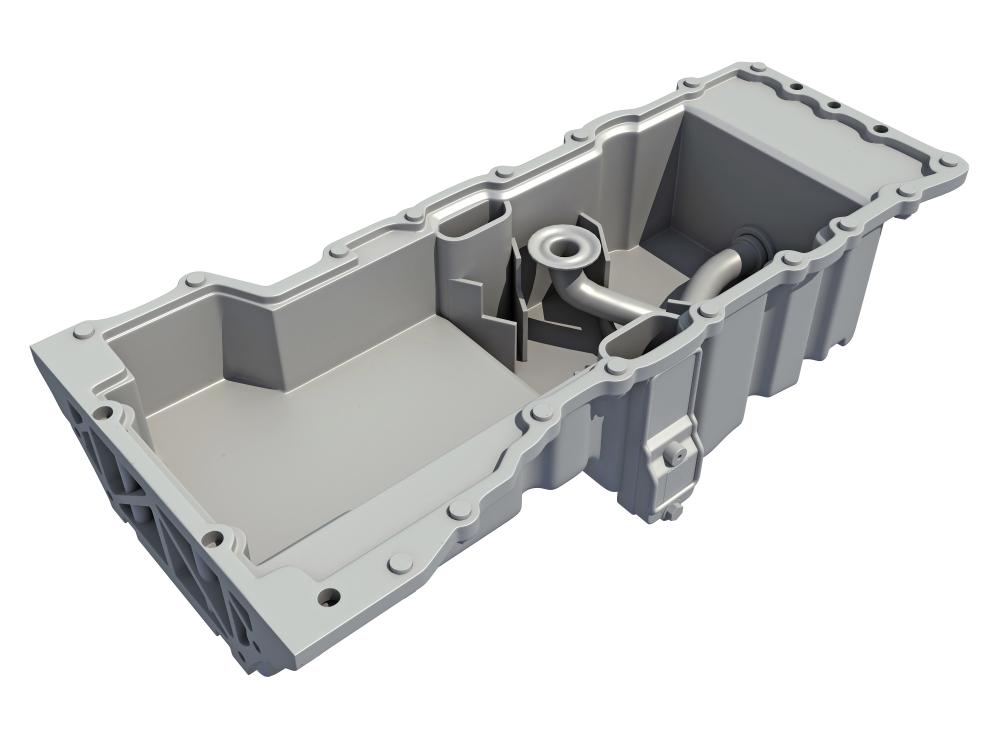

Low pressure aluminum casting is employed across a myriad of sectors. In the aerospace domain, it’s used for components that require lightweight yet strong parts, such as landing gear assemblies. The automotive industry benefits from this process in the creation of structural parts and engine components that demand high performance and reliability.

Aerospace Applications

In the realm of flight, every gram matters. Low pressure aluminum casting helps in manufacturing parts that not just meet but exceed the rigorous standards of the aerospace industry, contributing to the overall efficiency and safety of aircraft.

Automotive Performance

The automotive sector continuously seeks advancements in performance and fuel efficiency. Through low pressure aluminum casting, we’re able to produce parts that significantly reduce vehicle weight without compromising strength or safety, thus enhancing both performance and fuel efficiency.

The Process Explained

Low pressure aluminum casting at Protocast Inc. begins with the careful preparation of aluminum alloys, which are heated until molten. The molten metal is then transferred into a mold under controlled pressure, ensuring a steady and uniform fill. This meticulous process prevents defects and ensures the integrity of the cast piece.

Mold Design and Preparation

Crucial to the success of low pressure aluminum casting is the design and preparation of the mold. Our skilled technicians craft molds that not only accurately represent the desired geometry but also take into consideration the thermal dynamics of the casting process, ensuring superior results.

Control and Precision

The precision of low pressure aluminum casting lies in the control of pressure and temperature throughout the process. This control is fundamental to achieving the desired outcomes in terms of structural integrity and surface finish.

Why Choose Protocast Inc.?

Our commitment at Protocast Inc. to excellence in low pressure aluminum casting is unwavering. With a focus on quality, efficiency, and customer satisfaction, we strive to exceed expectations at every turn. Our ISO 9001:2015 certification and Itar Registration are testaments to our high standards.

Partnership and Collaboration

We view our relationship with clients as a partnership. By understanding their needs and objectives, we are able to offer tailored solutions that not only meet but surpass their requirements. This collaborative approach has been integral to our success and the success of our clients.

State-of-the-Art Technology

The integration of cutting-edge technology in our casting processes enables us to maintain a competitive edge. From advanced mold design software to precision temperature control equipment, we leverage technology to enhance our capabilities and the quality of our castings.

- Aerospace and Automotive: Producing lightweight, high-strength parts that contribute to efficiency and safety.

- Medical Equipment: Creating complex components for medical devices where precision and reliability are crucial.

- Consumer Products: Offering versatility in design and material for a wide variety of consumer goods.

At Protocast Inc., we’re proud to be “A Mile Above Other Foundries” in the metal casting industry. Whether your project involves a single part or 150,000, our dedication to producing flawless components remains the same. Discover the Protocast Inc. difference today.

What is the process of low pressure aluminum casting?

Low pressure aluminum casting is a precise and controlled process where molten aluminum is injected into a mold at lower pressures. This method starts with melting aluminum alloys until they’re fully liquid. The molten aluminum is then transferred into a mold. Care is taken to maintain a steady and uniform pressure, which ensures the molten metal fills every part of the mold evenly, capturing the intricate details and complex shapes of the desired component. This meticulous approach minimizes turbulence, resulting in casts with superior surface finishes and structural integrity. It’s a fine dance of temperature and pressure control, something we at Protocast Inc. have honed to an art form over many years.

What is the pressure for aluminium casting?

The pressure used in aluminum casting varies depending on the specific process being employed. In low pressure aluminum casting, the pressure is typically set between 15 to 100 kPa. This is significantly lower compared to high pressure die casting methods, where pressures can range from 20 to 90 MPa. The choice of lower pressure in our process is strategic; it allows for smoother filling of the mold, which not only enhances the detail and quality of the cast but also significantly reduces the chances of porosity within the final product. It’s about striking the perfect balance to achieve precision without compromising material integrity.

What are the advantages of low pressure die casting?

Low pressure die casting boasts several advantages that make it especially appealing for creating parts that demand high accuracy and integrity. Firstly, it achieves smoother surface finishes and greater detail clarity compared to high pressure methods, due to the gentler flow of molten metal into the mold. This also significantly reduces porosity, enhancing the mechanical properties and strength of the final product. Moreover, the use of permanent molds offers economic benefits by reducing both production times and costs, not to mention the design flexibility it affords. It allows us to precisely cater to complex geometries and intricate designs, which would be challenging or impossible with other casting methods. For industries where quality, precision, and efficiency are non-negotiable, low pressure die casting presents a compelling solution.

What is the best casting process for aluminum?

Identifying the “best” casting process for aluminum really depends on the project requirements, including the part’s complexity, desired precision, production volume, and cost considerations. For high-volume production of parts requiring detailed geometries and superior surface finish, low pressure aluminum casting stands out. It combines efficiency with versatility, enabling the production of components with intricate details and excellent material properties. However, for smaller batches or prototypes, processes like sand casting or investment casting might be more appropriate, offering lower upfront costs and flexibility. At Protocast Inc., we take pride in working closely with our clients to determine the most suitable casting process for their specific needs. It’s about leveraging the right technology and process to turn visionary designs into tangible products.

How are low pressure casting methods particularly beneficial in industries like aerospace and automotive?

In sectors like aerospace and automotive, where the balance between weight, strength, and reliability is critical, low pressure casting methods bring unparalleled benefits. For aerospace applications, reducing the weight of a part without compromising its strength or integrity can significantly impact fuel efficiency and overall performance. Low pressure aluminum casting allows us to produce lightweight, high-strength parts that meet these stringent requirements. In the automotive industry, the method supports the production of complex, durable components that contribute to vehicle safety, performance, and fuel efficiency. By enabling the creation of parts that precisely fit these demanding specifications, low pressure casting methods play a pivotal role in advancing innovation and efficiency in these cutting-edge industries.

Why should someone choose Protocast Inc. for their casting needs?

Choosing Protocast Inc. for casting needs comes down to a commitment to excellence, precision, and partnership. Our ISO 9001:2015 certification and Itar Registration underscore our dedication to the highest standards of quality and reliability. We’re not just a foundry; we’re your strategic partner, committed to understanding your objectives and exceeding your expectations. By integrating state-of-the-art technology and maintaining a focus on innovation, we ensure that our casting processes–especially low pressure aluminum casting–offer the flexibility, efficiency, and precision our clients demand. Whether your project involves a single prototype or mass production, our team is equipped to deliver outstanding results, making “A Mile Above Other Foundries” more than just a slogan–it’s our promise to you. Let’s turn your concepts into reality, together.

Resources

- NASA Space Flight – Explore aerospace advancements and news from NASA’s official space flight website.

- Society of Automotive Engineers (SAE) – Access resources and information on automotive engineering from the SAE organization.

- Medical Device Online – Discover insights and articles on medical device technology and innovation.

- Consumer Reports – Find product reviews and consumer information to make informed purchasing decisions.