Prototype Casting Inc. Employs The “Precision Sand” Or “No Bake Sand” To Make Rapid, High Quality Sand Castings In As Little As Three Days

Precision Sand or No Bake Sand is a fine grain sand combined with a two part urethane binder to make sand castings. Precision Sand Casting allows for larger castings with thicker walls and an approximately 200 micro inch surface finish.

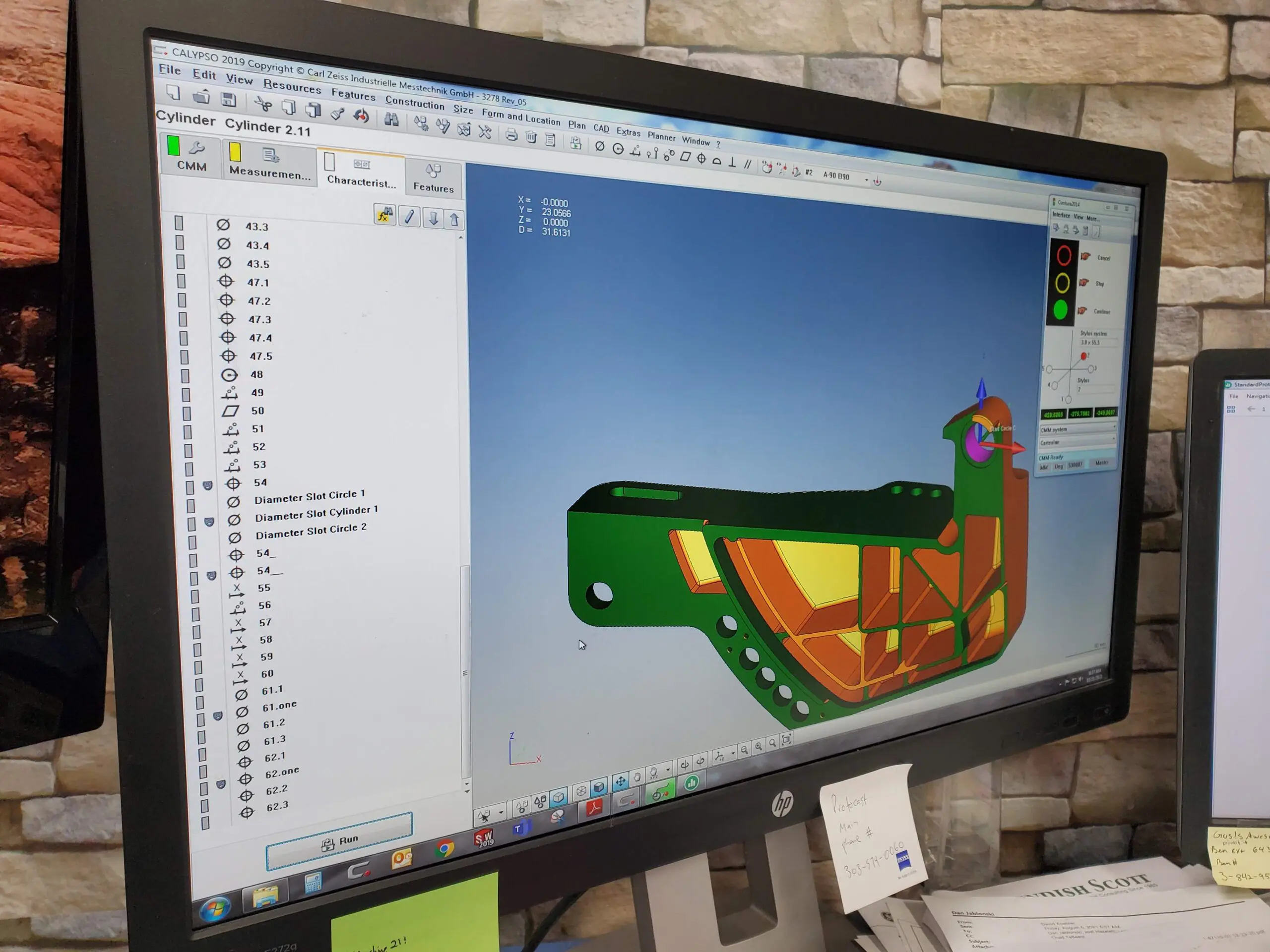

Coupled with the increased computer CPU speeds and improvements in CNC machines, prototype Casting Inc. can machine a positive image of an intended casting into a urethane modeling board once metal shrinkage and gating have been engineered into the mold design. ESI Quick Cast Computation fluid analysis, FEA, software is used to simulate casting solidification.

The precision Sand mold is framed up and the fine grain sand mixture is hand packed into the mold master. Once the sand binder has set, in about 20-30 minutes, the mold is assembled and set aside to have the molten metal poured.

After the casting has cooled to ambient temperature the sand mold is broken off the casting. After the gate and riser has been removed, the casting is cleaned up by hand and sent to the in house machine shop.

Advantages: Supports larger castings with thicker walls; Very few size limitations; Achieves best mechanical properties; Superior surface finish and dimensional tolerances than green-sand castings; Can produce our highest production quantities.