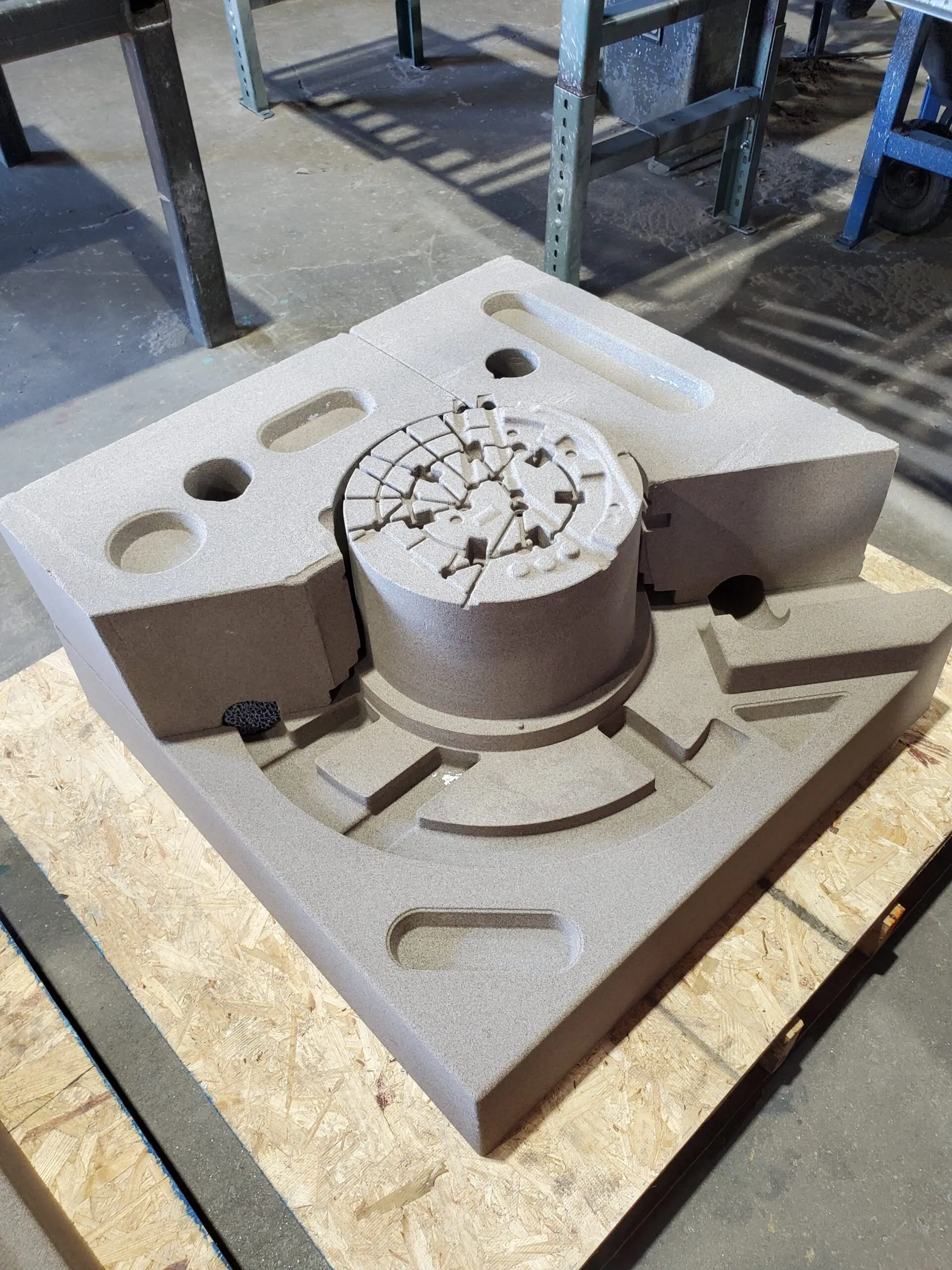

We recently began offering sand castings using a printed sand mold process. The process uses 3D Printer technology to print a sand mold directly onto a print bed. This process eliminates the need for hard tooling. The process also supports geometries that were once restricted to production investment casting. Complex cores and undercuts are all easily achieved using this state-of-the-art system. The process can produce a limited number of sand molds in as little as 5 days from receipt of an order.

Printed sand molds are appropriate for smaller quantities or for geometry that is not supportable using a traditional sand casting. The surface finish and mechanical properties are consistent with traditional sand castings, while the tolerances are much closer to air-set sand casting tolerances. This process is an excellent choice for larger castings that are too large to print in a wax pattern system.

The printer is capable of making individual molds up to ~ 70” x 39” x 27”, as well as printing multiple simultaneous molds inside the print envelope.