October 15, 2024 | Protocast Inc

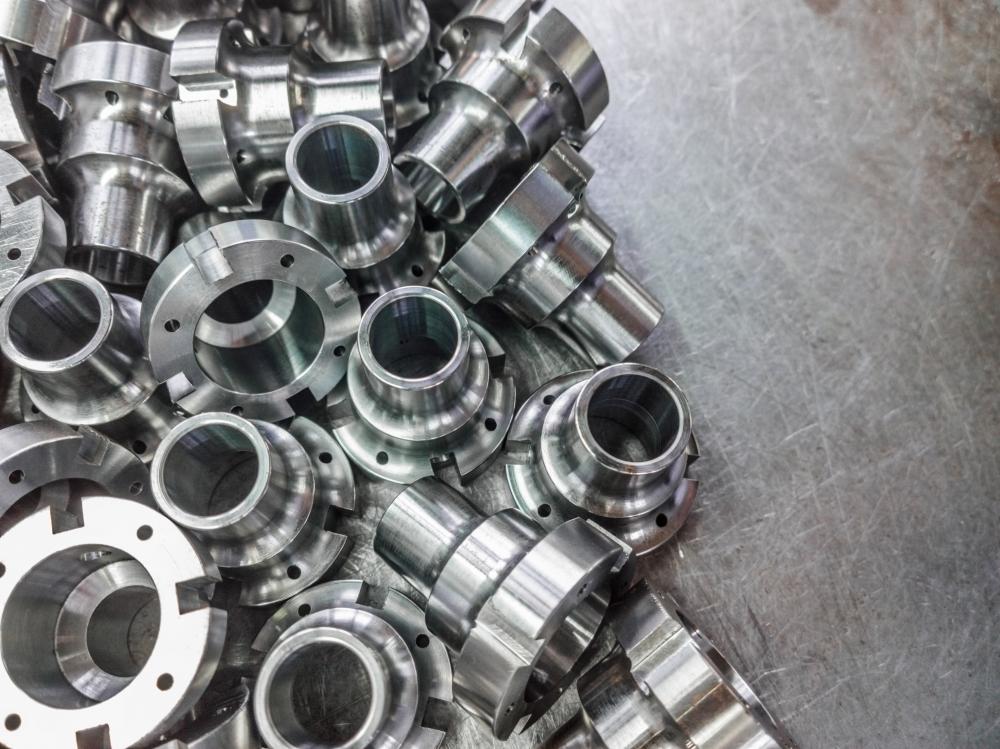

Aluminum Castings California

Exploring Aluminum Castings

At Protocast Inc., nestled a mile above other foundries in the bustling heart of Commerce City, CO, we’re not just casting aluminum–we’re crafting the future. Our work with aluminum castings is a testament to our commitment to quality, efficiency, and innovation. Aluminum castings are pivotal in various industries, including aerospace, automotive, agriculture, medical, and consumer products, due to their lightweight, strength, and corrosion resistance.

Types of Casting Processes

Our expertise in casting processes is diverse, intending to meet and exceed our customers’ unique needs. From Precision Sand Casting to Investment Casting, each technique offers distinct advantages tailored for specific applications. We thrive on the challenge of selecting the perfect process, whether it’s Die Casting for high-volume production or Permanent Mold Casting for superior surface finish and dimensional accuracy.

Advantages of Aluminum Castings

Aluminum castings stand out for their versatility and efficiency. The lightweight nature of aluminum, combined with its considerable strength, makes aluminum castings a preferred choice across many sectors. Especially in aerospace and automotive industries, where weight reduction without compromising strength is crucial, aluminum castings play an indispensable role.

Additionally, the corrosion resistance of aluminum enhances the longevity of products, ensuring they withstand harsh conditions without degradation. This attribute, coupled with aluminum’s excellent thermal conductivity, opens up a realm of applications, from heat exchangers in aerospace to engine components in automotive applications.

Quality Assurance in Casting

At Protocast Inc., our commitment to quality is unwavering. Our ISO 9001:2015 certification and ITAR Registration underscore our dedication to maintaining the highest standards in manufacturing. We understand that the essence of exceptional aluminum castings lies not only in the precision of the casting process but also in rigorous quality assurance protocols. Our in-house team meticulously inspects each casting, ensuring that every product not only meets but exceeds customer expectations. This dedication to quality is what sets us apart, a mile above other foundries.

Custom Solutions for OEMs

Understanding the varied needs of global OEMs has allowed us to tailor custom casting solutions that align with their specific requirements. Whether it’s a prototype or a high-volume production run, our team works closely with each client to determine the most efficient casting method for their application. This collaborative approach ensures that each project is met with innovative solutions, timely delivery, and cost-effectiveness, embodying our spirit of partnership.

Our experience with a wide array of industries from aerospace to consumer products has honed our ability to anticipate and meet the unique challenges presented by each sector. By embracing complexity, we’ve developed a knack for delivering projects that others might shy away from, further solidifying our reputation as a trusted partner in aluminum castings.

Innovation in Aluminum Casting

Innovation lies at the heart of what we do at Protocast Inc. Leveraging the latest in casting technology and staying abreast of industry trends allows us to offer cutting-edge solutions to our clients. From employing 3D printed sand casting molds for rapid prototyping to exploring eco-friendly casting methods that reduce environmental impact, our quest for innovation is relentless. It’s this forward-thinking approach that enables us to tackle the most daunting of projects with confidence and skill.

Environmental Impact of Casting

Environmental stewardship is a core principle at Protocast Inc. We recognize the importance of minimizing our environmental footprint throughout the casting process. By optimizing our manufacturing processes and utilizing recyclable materials, we strive to reduce waste and energy consumption. This commitment to sustainability is not just good for the planet–it’s also what our clients expect from a leader in the industry.

The Future of Aluminum Castings

The future of aluminum castings is bright, with ongoing advancements in casting technologies and materials science. As industries continue to evolve, the demand for lighter, stronger, and more environmentally friendly materials will grow. Aluminum castings are well-positioned to meet these challenges head-on, with innovative foundries like Protocast Inc. leading the way.

Embracing change, pushing the boundaries of technology, and staying committed to quality are the keys to our continued success in the aluminum castings industry. As we look to the future, we’re excited about the possibilities it holds and our role in shaping it.

Why Partner with Protocast Inc.?

Choosing Protocast Inc. for your aluminum castings needs means partnering with a company that is dedicated to excellence at every step of the process. Our track record of delivering high-quality, complex castings on time and within budget speaks for itself. Our team is ready to bring its expertise, innovation, and passion to your next project, ensuring that we continue to be “A Mile Above Other Foundries.”

Contact us today to learn more about how we can assist with your aluminum castings requirements, and let us help you turn your concepts into reality.

What are aluminum castings used for?

At Protocast Inc., our aluminum castings find their way into a myriad of applications across various sectors. It’s fascinating to see how a single material can be so versatile. For instance, in the aerospace industry, our lightweight yet strong castings are used to create components that endure the rigors of flight without adding unnecessary weight. Automotive manufacturers turn to us for engine parts and structural components that benefit from aluminum’s strength and corrosion resistance. Beyond these, we also craft pieces for medical devices, agricultural machinery, and consumer products. Imagine everything from the frame of your car to the casing of your smartphone – that’s the reach of our aluminum castings. It’s not just about making parts; it’s about crafting the future of industries.

What are the disadvantages of aluminium casting?

While aluminum casting offers myriad benefits, it does come with its set of challenges. For one, aluminum’s high thermal conductivity, while advantageous for heat dissipation applications, can pose challenges in managing solidification during the casting process. This can lead to defects in the finished casting if not properly controlled. Additionally, aluminum is more susceptible to hot cracking compared to some other metals, requiring careful attention to mold design and processing parameters. It’s a dance of science and art, ensuring the molody of temperature and timing is just right. But with our expertise at Protocast Inc., we’ve turned these potential disadvantages into manageable aspects of our craft, ensuring the highest quality of castings for our clients.

How do you make aluminum castings?

The making of aluminum castings is a process we’ve refined to an art at Protocast Inc. It begins with the creation of a mold, which can be designed using various methods like sand casting, die casting, or investment casting, depending on the required precision and surface finish. We then melt high-quality aluminum alloy and pour it into the mold, where it takes the shape of the desired part. After cooling, the casting is removed from the mold, revealing a part that, while still requiring finishing touches, embodies the intricate details envisioned by our clients. This process demands not just technical skill but a deep understanding of the material and the end use of the part, ensuring each casting meets the exact specifications and quality standards required.

Is aluminium casting expensive?

The cost of aluminum casting can vary widely based on several factors, including the complexity of the design, the type of casting process used, and the volume of parts produced. At Protocast Inc., we work closely with our clients to select the most cost-effective casting method for their project, balancing quality, precision, and budget. While initial setup costs for some casting processes, such as die casting, can be higher due to the need for specialized tooling, the per-part cost often decreases significantly with larger production runs. Hence, while not the cheapest method on the market, aluminum casting offers tremendous value through durability, versatility, and the ability to create complex, lightweight parts efficiently.

What sets your custom casting solutions apart?

What truly sets our custom casting solutions at Protocast Inc. apart is our collaborative approach combined with our technical expertise. We don’t just produce parts; we partner with our clients to understand their unique challenges and objectives. This understanding allows us to recommend the ideal casting process and aluminum alloy, tailored to their specific application. Our dedication to innovation means we’re constantly exploring new techniques and technologies, from 3D printed sand molds for rapid prototyping to eco-friendly casting practices. It’s this blend of partnership, expertise, and innovation that has earned us the reputation of being “A Mile Above Other Foundies,” allowing us to tackle projects others might shy away from with confidence and excellence.

Resources

- National Institute of Standards and Technology (NIST) – The NIST provides valuable information on standards and measurements in various industries, including casting processes.

- ASM International – ASM International is a society that provides materials information and knowledge for various industries, including aluminum casting.

- Association for Iron & Steel Technology (AIST) – AIST offers resources and education on iron and steel technologies, which can be applicable to aluminum casting processes.

- The Minerals, Metals & Materials Society (TMS) – TMS provides resources and research on materials science and engineering, including information on aluminum castings.

- The Aluminum Association – The Aluminum Association offers industry standards and resources related to aluminum production and casting processes.