October 15, 2024 | Protocast Inc

Die Cast Aluminum Kentucky

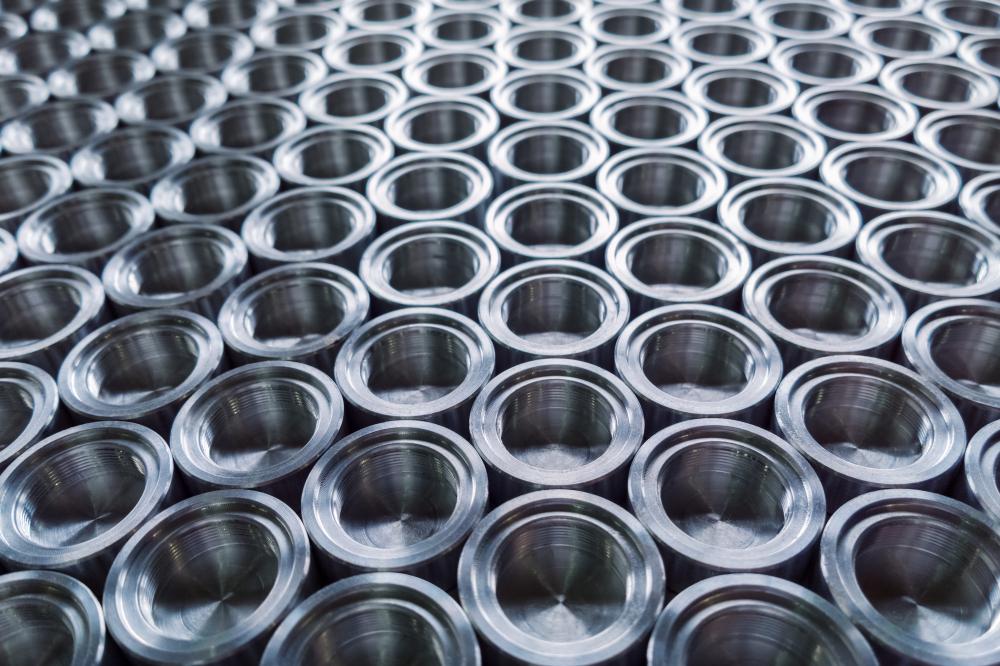

What is Die Cast Aluminum?

Die cast aluminum is a cornerstone of industrial manufacturing, offering a unique blend of durability, efficiency, and precision. At Protocast Inc., we take pride in our expertise in delivering high-quality die cast aluminum parts to a variety of industries including aerospace, automotive, agriculture, medical, and consumer products. This quick guide dives into the essentials of die cast aluminum, its advantages, and why it continues to be a preferred material for countless applications.

Advantages of Die Cast Aluminum

The popularity of die cast aluminum can be attributed to its several advantageous properties. Primarily, its exceptional strength-to-weight ratio makes aluminum castings ideal for high-performance applications where weight is a critical consideration. Additionally, the material’s natural corrosion resistance extends the life of products while reducing the need for additional finishing processes.

Corrosion Resistance and Electrical Conductivity

One cannot discuss the benefits of die cast aluminum without highlighting its excellent corrosion resistance and superior electrical conductivity. These properties make it an excellent choice for electronic housings and connectors, which require both durability and effective electrical performance. At Protocast Inc., we leverage these characteristics to produce components that not only meet but exceed our clients’ expectations.

Lightweight and Durable

Die cast aluminum’s lightweight nature, combined with its durability, allows for the creation of parts that are both easy to handle and long-lasting. This is particularly beneficial in the automotive and aerospace industries, where reducing weight can significantly enhance performance and fuel efficiency.

Custom Casting Solutions

At Protocast Inc., we understand that each project is unique. That’s why we offer a range of casting processes, including precision sand casting, low pressure die casting, and investment casting, among others. Our team works closely with clients to select the best method for their specific needs, ensuring optimal results for both prototype and production runs.

Quality Assurance

Our commitment to quality is reflected in our ISO 9001:2015 certification and ITAR registration. We employ rigorous quality control measures throughout the manufacturing process to ensure that every part meets the highest standards of precision and excellence.

Considerations for Choosing Die Cast Aluminum

Material Properties

When selecting materials for a project, it’s crucial to consider the specific properties required for the application. Die cast aluminum’s high thermal and electrical conductivity, along with its good strength-to-weight ratio, make it an excellent choice for a wide range of uses.

Design Complexity

Die casting allows for the production of complex shapes with high levels of accuracy and detail. This capability is a key reason why industries favor die cast aluminum for components with intricate designs.

Innovative Applications of Die Cast Aluminum

From lightweight automotive parts that enhance fuel efficiency to durable components for aerospace applications, die cast aluminum plays a critical role in advancing technology and innovation in various fields. At Protocast Inc., we continuously explore new ways to apply our expertise in die casting to meet the evolving needs of our clients.

Sustainability Aspects

Aluminum is fully recyclable and reusable in production, which contributes to its appeal as an environmentally friendly material. By prioritizing the use of die cast aluminum, we support sustainable manufacturing practices that benefit both our clients and the planet.

Partnering with Protocast Inc.

Choosing Protocast Inc. for your die cast aluminum needs means partnering with a team that is dedicated to excellence. Our extensive experience, combined with a commitment to innovative solutions and sustainable practices, makes us a leader in the casting industry. Contact us today to learn how we can help bring your project to life.

- Extensive Range of Casting Processes

- ISO 9001:2015 Certified Quality Assurance

- Recyclable and Environmentally Friendly Materials

- Customized Solutions for Diverse Industry Needs

Is die cast aluminum better than aluminum?

When we talk about die cast aluminum versus aluminum, the conversation often centers on the specific application and manufacturing process rather than one material being inherently “better” than the other. Die casting involves forcing molten aluminum into a mold under high pressure, a process that allows for high precision, complex shapes, and excellent surface finish right out of the mold. This method is particularly beneficial for producing large volumes of parts where consistency and detail are critical. On the other hand, aluminum in its basic form can be used in a variety of applications, benefiting from its natural properties like light weight and corrosion resistance. The choice between die cast aluminum and other forms of aluminum really depends on the project requirements. For instance, if you need complex, detailed parts in large quantities, die cast aluminum might be the way to go. Conversely, for projects requiring large, thick pieces, other manufacturing techniques might be more suitable.

What is aluminium die cast?

Aluminum die casting is a metal casting process that involves melting aluminum and injecting it under high pressure into a steel mold called a die. This process allows for the production of complex shapes with a high level of accuracy and smoothness. One of the reasons we at Protocast Inc. favor die casting is its ability to produce parts with thin walls and those that require a high level of detail, which might be challenging to achieve with other casting methods. Additionally, die cast parts are durable and have an excellent surface finish, reducing the need for additional machining and processing. This process is widely used across various industries, including automotive, aerospace, and consumer electronics, for parts like engine components, gearboxes, and housing for electronic devices. It’s a technique that has revolutionized the way we think about manufacturing and design, allowing for the efficient production of complex, high-quality parts.

Is die cast aluminium cookware safe?

This is a common concern, and it’s important to address the safety of die cast aluminum cookware. The simple answer is yes, die cast aluminum cookware is safe for cooking when used properly. However, it’s essential to ensure that the cookware is coated with a non-reactive layer, such as a non-stick or enamel coating, to prevent aluminum from coming into direct contact with food. Uncoated aluminum can react with acidic foods, leading to a slight metallic taste. But the amount of aluminum that potentially leeches into food is minimal and generally considered safe by health standards. It’s also worth noting that aluminum’s excellent heat conductivity makes it a popular choice for cookware, providing even heating and reducing the risk of hot spots that can burn food. As with any cookware, using it as intended and following the manufacturer’s guidelines is key to ensuring safety and longevity.

What is the difference between aluminum and cast aluminum?

Understanding the difference between aluminum and cast aluminum is crucial in selecting the right material for your project. Aluminum refers to the pure metal and its alloys in various forms, including sheets, plates, and foils, which can be used in everything from packaging to construction. Cast aluminum, on the other hand, specifically refers to aluminum alloys that have been melted and poured into a mold to create a particular shape. The term “cast” refers to the process rather than the material itself. The casting process allows for the aluminum to be shaped with a high level of detail and complexity that would be difficult or impossible to achieve with other manufacturing methods. Additionally, cast aluminum parts benefit from the material’s lightweight and corrosion-resistant properties, but with added strength and durability due to the casting process. This makes cast aluminum an excellent choice for intricate designs and applications requiring a blend of strength, weight, and resistance to the elements.

How does the sustainability of die cast aluminum contribute to its popularity?

In today’s increasingly eco-conscious world, the sustainability of materials is a significant factor in their popularity, and die cast aluminum is no exception. Aluminum is one of the most recyclable materials available, offering the possibility to be reused without loss of quality or properties. This aspect of aluminum contributes to its appeal across industries striving for greener manufacturing processes. At Protocast Inc., we recognize the importance of sustainable practices, prioritizing the use of recyclable materials in our casting processes. The energy required to recycle aluminum is a fraction of that needed to produce primary aluminum, which significantly reduces the carbon footprint associated with die cast aluminum parts. Furthermore, the durability and longevity of die cast aluminum parts mean less frequent replacements, leading to less waste over time. This cycle of recycling and reusability positions die cast aluminum as a front-runner in the march towards sustainable manufacturing and product development.

What does the future hold for die cast aluminum in industry innovation?

Looking to the future, the potential for die cast aluminum in industry innovation is vast. As industries continue to push the boundaries of technology and design, the versatility and adaptability of die cast aluminum make it a material well-suited to meet these evolving demands. In the aerospace and automotive sectors, the drive for lighter, more fuel-efficient vehicles is expected to increase the use of die cast aluminum parts. Similarly, in electronics, the need for durable, lightweight, and heat-dissipating materials for housings and components will likely continue to favor die cast aluminum. Moreover, advancements in casting technologies and processes promise to further enhance the precision, efficiency, and environmental friendliness of die casting. At Protocast Inc., we are excited to be at the forefront of these developments, leveraging our expertise to explore new applications for die cast aluminum and contribute to the next wave of industrial innovation. The future looks bright for die cast aluminum, and we’re committed to exploring every avenue to ensure that our clients benefit from the very best the industry has to offer.

Resources

- National Transportation Safety Board (NTSB) – The NTSB is an independent federal agency tasked with investigating transportation accidents to determine probable causes and recommend safety improvements.

- U.S. Environmental Protection Agency (EPA) – The EPA works to protect human health and the environment by enforcing regulations and conducting research on environmental issues.

- National Institutes of Health (NIH) – The NIH is the primary agency for biomedical and public health research in the United States, funding and conducting studies to improve health outcomes.

- National Institute of Standards and Technology (NIST) – NIST promotes innovation and industrial competitiveness by advancing measurement science, standards, and technology in various sectors.