October 15, 2024 | Protocast Inc

Gravity Die Casting Ohio

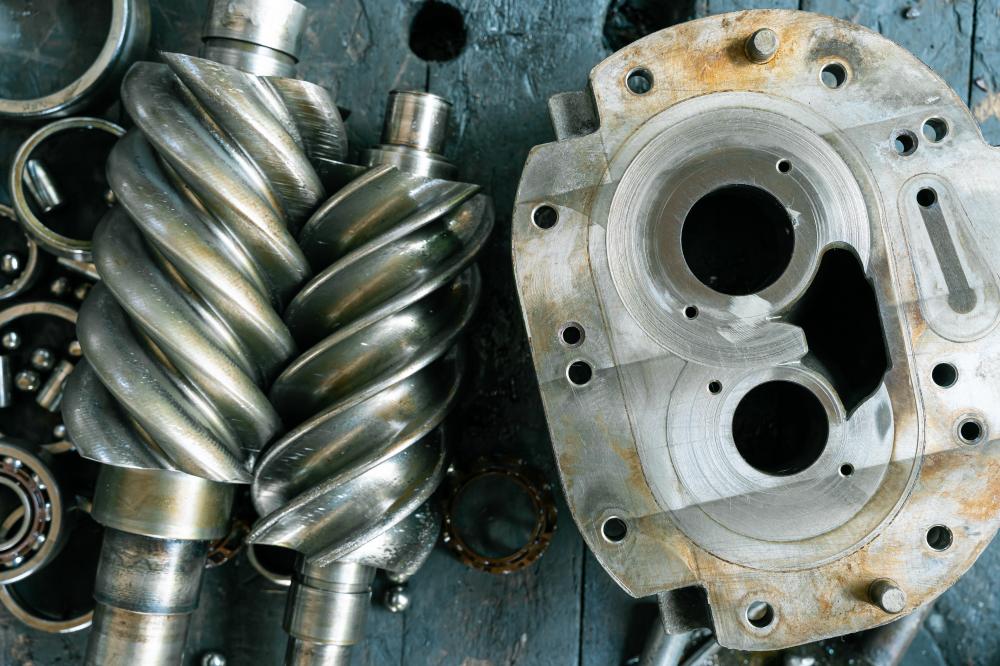

The Essence of Gravity Die Casting

At Protocast Inc., nestled in Commerce City, CO, we pride ourselves on pioneering advanced methods in gravity die casting, aiming to redefine precision and efficiency in the industry. Our journey into the realm of metal casting, specifically gravity die casting, encapsulates our mission to deliver unparalleled quality and innovation in all our endeavors. This method, central to our operations, utilizes the fundamental force of gravity to achieve metal parts that are not just components but embodiments of engineering precision.

Advantages of Gravity Die Casting

Gravity die casting holds a special place in our heart for several reasons. The inherent nature of the process, relying on gravity to fill the mold, brings about a level of denseness and strength in cast parts that is often unmatched. The absence of high-pressure injection means that the metal solidifies in a less turbulent environment, leading to superior structural integrity and an exemplary surface finish that our clients cherish.

Moreover, the repeatability of this process allows us to sustain high levels of quality control across batches, ensuring that each part is a testament to Protocast Inc.’s commitment to excellence. This process is especially beneficial when working with alloys of aluminum and zinc, offering the precision required for industries demanding the highest standards, such as Aerospace and Automotive.

Challenges and Solutions

Meeting Client Expectations

One of the perpetual challenges we face in gravity die casting is aligning with the exacting demands of our clients’ projects. Each design presents its unique challenges, from intricate geometries to stringent strength specifications. Our approach involves an in-depth consultation process, leveraging years of experience and the latest in 3D simulation software to preemptively address potential issues, ensuring a seamless transition from design to production.

Material Selection and Optimization

Choosing the right material is pivotal in gravity die casting. Our expertise lies in not just understanding the properties of various alloys, but in discerning the nuanced ways in which these materials respond to the casting process. This insight allows us to make informed recommendations to our clients, ensuring the final product not only meets but exceeds expectations in performance and durability.

Gravity Die Casting Applications

The versatility of gravity die casting is exemplified by its broad application across multiple industries. From aerospace components that demand the utmost precision and strength, to automotive parts requiring high durability and corrosion resistance, our gravity die casting services have supported the development of groundbreaking products. Our involvement in the medical and consumer products sectors further demonstrates the adaptability of this process, where the quality of finish and material integrity are paramount.

Why Choose Protocast Inc.?

Our dedication to pushing the boundaries of gravity die casting stems from a deep-rooted passion for innovation and quality. Protocast Inc. is not just a foundry; we are a team of specialists committed to bringing your projects to life, providing guidance and expertise every step of the way. Our ISO 9001:2015 certification and Itar Registration are testament to our unwavering focus on quality and reliability.

Choosing Protocast Inc. means partnering with a team that puts your needs first, ensuring each project benefits from decades of casting experience and a relentless pursuit of perfection. Our facility in Commerce City, CO, is equipped with state-of-the-art technology, enabling us to handle projects of any scale while maintaining the highest standards of quality and efficiency.

Innovative Approaches to Gravity Die Casting

In our quest to stay “A Mile Above Other Foundries,” we constantly explore innovative approaches to enhance our gravity die casting processes. This includes investing in advanced machinery, adopting sustainable practices to minimize environmental impact, and developing proprietary techniques that push the capabilities of traditional gravity die casting. Our approach is holistic, considering not just the technical aspects, but also the environmental and economic implications of our methods.

Personal Touch in Every Project

At Protocast Inc., we believe that the success of our gravity die casting projects is not solely the result of technical prowess but also the personal dedication we bring to each job. Our clients’ visions are the driving force behind our efforts, inspiring us to deliver results that embody their ambitions. Through collaborative relationships, we navigate the complexities of each project, offering insights and solutions that align with our clients’ goals.

The satisfaction of seeing a project come to fruition, knowing that we’ve met or exceeded our clients’ expectations, is the true reward for our work. Our dedication to craftsmanship, innovation, and service excellence makes us not just a provider, but a partner in our clients’ success.

Conclusion from Protocast Inc.

Gravity die casting is more than just a manufacturing process at Protocast Inc.; it’s a cornerstone of our operation that exemplifies our commitment to quality, innovation, and customer satisfaction. As we continue to serve industries with ever-increasing demands for precision and reliability, our focus remains on advancing our capabilities, ensuring that our clients receive the best possible outcomes for their projects. Contact us today to discuss how we can bring your vision to life with the unparalleled precision and quality of gravity die casting.

What is gravity die casting?

Gravity die casting is a process we hold dear here at Protocast Inc., leveraging the fundamental force of gravity to channel molten metal into a pre-designed mold. Unlike other casting processes, it doesn’t rely on high-pressure methods to fill the mold. This fundamental difference not only speaks to the very essence of metal casting but also enables us to produce parts with exceptional denseness and structural integrity. Imagine pouring pancake batter into a skillet – it’s that natural flow, guided by gravity, that ensures the batter spreads evenly to form the perfect shape. That’s akin to how gravity die casting works, creating components that closely adhere to their design specifications with remarkable accuracy.

What is the difference between gravity die casting and pressure die casting?

Many of our clients often ponder over the choice between gravity die casting and pressure die casting. The pivotal distinction lies in how the molten metal is introduced into the mold. In gravity die casting, the metal flows into the mold under the earth’s gravitational force alone, offering a serene environment for the metal to solidify. Pressure die casting, on the other hand, involves forcing the metal into the mold under high pressure. This difference significantly impacts the final outcome – while gravity die casting is celebrated for its superior surface finish and structural integrity, pressure die casting is known for its ability to produce more intricate designs with thinner walls. It’s akin to choosing between a hand-painted masterpiece and a high-definition photograph; each has its unique advantages depending on the desired outcome.

What are the disadvantages of gravity die casting?

While gravity die casting has many feathers in its cap, it’s also accompanied by certain limitations. One of the main challenges we encounter is the restriction it places on the complexity of cast shapes. Due to the nature of gravity filling, designs with undercuts or severe complexity can be difficult to achieve. Additionally, the initial setup and tooling costs can be higher than other casting methods, making it less economically feasible for small production runs. It’s somewhat akin to setting up a gourmet kitchen – the upfront investment is significant, but it’s worth it for the quality and precision of the dishes you can produce.

Is gravity die casting accurate?

Accuracy is a hallmark of gravity die casting, a point of pride for us at Protocast Inc. Thanks to the controlled environment in which the molten metal is introduced to the mold, the castings we produce are not only true to the original design but also possess a superior surface finish and dimensional stability. It’s much like baking a cake with a tried-and-tested recipe; you can expect consistent results every time. However, the inherent precision of the process also means that the design and preparation of the molds need to be executed with the utmost care and expertise to ensure the final product meets the stringent standards our clients demand.

What industries benefit the most from gravity die casting?

Gravity die casting has found its champions across a myriad of industries, thanks to its versatility and the quality of components it can produce. Particularly, the Aerospace and Automotive sectors, where the integrity and durability of parts are non-negotiable, have seen significant benefits. Additionally, its applications in the Medical and Consumer Products industries underscore the process’s adaptability, catering to needs ranging from precision medical devices to durable consumer goods. It’s a bit like finding a Swiss Army knife; once you understand its capabilities, you find its applications are nearly limitless.

How does Protocast Inc. ensure quality in gravity die casting?

At Protocast Inc., ensuring quality in our gravity die casting processes is multi-faceted, involving meticulous planning, advanced technologies, and a culture of excellence. From the initial design consultation to the final quality check, every step is guided by our ISO 9001:2015 certification standards. We harness the power of 3D simulation software to foresee and address potential issues before they arise. Picture an orchestra, where every instrument plays its part in harmony; that’s how we approach each project, with every team member contributing their expertise to ensure the final product performs flawlessly in the applications it’s designed for.

What does the future hold for gravity die casting?

The future of gravity die casting is as bright as it is dynamic, shaped by ongoing advancements in technology and sustainable practices. At Protocast Inc., we are at the forefront of exploring innovative approaches to enhance not just the granularity of detail and efficiency of our processes but also their environmental footprint. Imagine a world where every casting not only meets the highest standards of precision but also contributes to a healthier planet. That’s the future we’re working towards, with every step we take in advancing our gravity die casting capabilities.

Resources

- National Institute of Standards and Technology (NIST) – The NIST website provides valuable information on standards and guidelines related to manufacturing processes like gravity die casting.

- ASM International – ASM International is a leading professional organization for materials scientists and engineers, offering resources on materials selection and optimization for casting processes.

- Aerospace Manufacturing and Design – This website offers insights into the aerospace industry and the application of gravity die casting in producing high-precision components for aircraft.

- Society of Automotive Engineers (SAE) – SAE provides information on automotive engineering standards and practices, including the use of gravity die casting in manufacturing automotive parts.